The Future Of Robots In Nike Shoe Manufacturing: A Realistic Look

Table of Contents

Current Robotic Applications in Nike Shoe Manufacturing

Nike's commitment to innovation extends to its manufacturing processes. Robots are already playing a significant role, enhancing efficiency and quality across various stages of shoe production.

Automation in Cutting and Stitching

Robotic arms and automated cutting machines are revolutionizing the initial stages of shoe manufacturing. These advanced systems offer:

- Increased precision: Robotic cutting minimizes material waste and ensures consistent component sizes.

- Reduced material waste: Precise cutting leads to less material discarded, improving sustainability and reducing costs.

- Higher speed of production: Automated systems significantly increase the speed of cutting and stitching compared to manual processes.

While specific robotic systems used by Nike are often kept confidential for competitive reasons, industry-standard automated cutting tables and six-axis robotic arms are commonly employed in similar large-scale footwear manufacturing. However, limitations remain; the intricate nature of some shoe designs still presents challenges for complete automation in this area.

Assembly and Glue Application

Robots are increasingly vital in assembling shoe parts and applying adhesives. This automation brings several advantages:

- Improved consistency: Robots apply consistent pressure and glue amounts, resulting in more durable and reliable shoe construction.

- Reduced human error: Automated assembly minimizes the risk of human errors leading to defects or inconsistencies.

- Faster assembly lines: Robots can work continuously at a higher speed than human workers, significantly speeding up the assembly process.

A key challenge in this area is the dexterity required to handle various materials and components with the necessary precision. The development of more sophisticated robotic grippers and advanced control systems is crucial to overcome this.

Quality Control and Inspection

Robotic vision systems are transforming quality control in Nike's factories. These systems offer:

- Detection of flaws: Advanced cameras and AI algorithms identify even subtle defects that might be missed by human inspectors.

- Faster inspection rates: Robotic vision systems can inspect shoes much faster than manual methods, improving throughput.

- Improved quality consistency: Automated inspection ensures consistent quality standards across all production batches.

Advancements in AI-powered defect detection are leading to more accurate and efficient quality checks, minimizing the number of faulty shoes reaching consumers.

Future Trends: Advanced Robotics and AI in Nike's Factories

Looking ahead, the integration of advanced robotics and AI will further revolutionize Nike's shoe manufacturing.

AI-Powered Design and Customization

AI has the potential to personalize shoe designs and manufacturing based on vast amounts of customer data. This could lead to:

- Mass customization possibilities: Customers could design their own shoes with unique features and specifications.

- Reduced inventory costs: Mass customization reduces the need for large inventories of pre-manufactured shoes.

- Increased customer satisfaction: Personalized products cater to individual needs and preferences, enhancing customer loyalty.

The integration of 3D printing and other advanced manufacturing techniques will further enable this level of customization, leading to on-demand production.

Collaborative Robots (Cobots) and Human-Robot Interaction

Cobots are designed to work alongside human workers, enhancing efficiency and safety. This collaborative approach offers several benefits:

- Improved ergonomics: Cobots can handle repetitive or physically demanding tasks, reducing strain on human workers.

- Reduced repetitive strain injuries: Automation of repetitive tasks reduces the risk of workplace injuries.

- Increased productivity: Human workers can focus on more complex and creative tasks while cobots handle routine operations.

Upskilling and reskilling the workforce is crucial to ensure a successful transition to a human-robot collaborative environment.

Predictive Maintenance and Data Analytics

Data analytics and AI can predict potential equipment failures, allowing for proactive maintenance and minimizing downtime. This offers:

- Reduced downtime: Predictive maintenance prevents unexpected equipment failures, ensuring continuous production.

- Improved equipment lifespan: Proactive maintenance extends the lifespan of expensive robotic equipment.

- Cost savings: Reduced downtime and extended equipment lifespan lead to significant cost savings.

The use of sensors and IoT devices throughout the factory environment provides the data needed for accurate predictive modeling.

Challenges and Considerations

While the benefits of robotics in Nike shoe manufacturing are substantial, several challenges need to be addressed:

High Initial Investment Costs

Implementing robotic systems requires significant upfront investment in equipment, software, and training. This can be a barrier for smaller companies or those with limited resources.

Job Displacement Concerns

Automation may lead to job losses in certain areas. Addressing this requires proactive workforce retraining and upskilling initiatives to prepare workers for new roles in the evolving manufacturing landscape.

Integration and Implementation Challenges

Integrating new robotic systems into existing manufacturing processes can be complex and time-consuming. Careful planning and effective project management are essential for a smooth transition.

Conclusion

The future of robots in Nike shoe manufacturing is bright, promising increased efficiency, improved quality, and greater customization possibilities. However, the high initial investment costs, potential job displacement, and integration challenges need careful consideration. To realize the full potential of robotics while mitigating potential negative impacts, a strategic approach that prioritizes worker retraining and sustainable automation practices is crucial. To understand the full impact and ensure a responsible transition, continued discussion and research on the future of robots in Nike shoe manufacturing are crucial.

Featured Posts

-

5 Key Economic Points From The English Language Leaders Debate

Apr 22, 2025

5 Key Economic Points From The English Language Leaders Debate

Apr 22, 2025 -

Understanding The Just Contact Us Phenomenon Tik Tok And Tariff Evasion

Apr 22, 2025

Understanding The Just Contact Us Phenomenon Tik Tok And Tariff Evasion

Apr 22, 2025 -

Zuckerbergs Next Chapter Navigating The Trump Presidency

Apr 22, 2025

Zuckerbergs Next Chapter Navigating The Trump Presidency

Apr 22, 2025 -

The Next Pope How Francis Papacy Will Shape The Conclave

Apr 22, 2025

The Next Pope How Francis Papacy Will Shape The Conclave

Apr 22, 2025 -

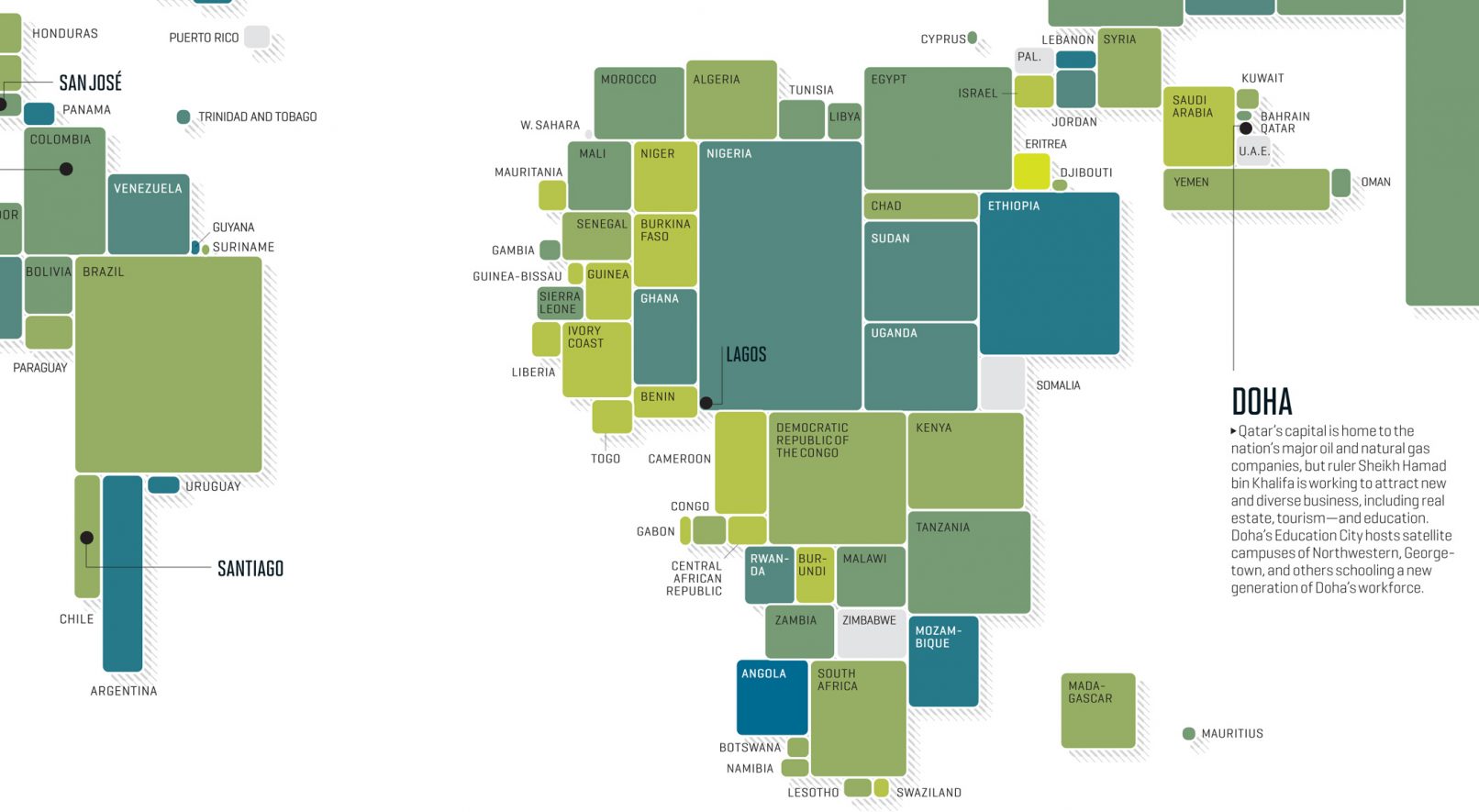

Mapping The Countrys Hottest New Business Locations

Apr 22, 2025

Mapping The Countrys Hottest New Business Locations

Apr 22, 2025