Nike Sneaker Production: Where Robots Fall Short (and Where They Excel)

Table of Contents

Areas Where Robots Excel in Nike Sneaker Production

Robots are transforming many facets of Nike's manufacturing operations, boosting efficiency and quality.

Automated Assembly Line Processes

Robotic automation has significantly streamlined the assembly line. Repetitive tasks like stitching, gluing the midsole and upper, and attaching soles are now performed with increased speed and precision by robots. This leads to several key advantages:

- Increased Speed: Robots work tirelessly at a consistent pace, significantly increasing production output compared to manual labor.

- Reduced Human Error: The precision of robotic arms minimizes errors in stitching, gluing, and other assembly steps, resulting in fewer defects.

- Improved Consistency: Each sneaker receives the same level of attention and precision, leading to a more uniform final product across the entire production run. This is crucial for maintaining Nike's quality standards.

- Enhanced Quality Control: Automated processes allow for more rigorous and consistent quality control checks during each stage of the assembly process.

This robotic automation in the Nike production process contributes significantly to manufacturing efficiency and improved quality control.

Material Handling and Logistics

Beyond the assembly line, robots are revolutionizing material handling and logistics within Nike's factories and warehouses.

- Automated Storage and Retrieval Systems (AS/RS): These systems optimize warehouse space and retrieval times, ensuring materials are readily available for the assembly process.

- Automated Guided Vehicles (AGVs): AGVs transport materials efficiently throughout the factory, minimizing manual handling and improving overall workflow.

- Improved Supply Chain Optimization: Efficient material handling directly impacts supply chain optimization, reducing lead times and minimizing disruptions.

- Reduced Labor Costs: Automation reduces the need for extensive manual labor in warehouse operations, resulting in significant cost savings.

The integration of robotics in logistics is key to streamlining Nike's supply chain and optimizing its production process.

Data Analysis and Predictive Maintenance

Robots are not just physical workers; they are also powerful data collectors. Sensors on robotic arms and other machinery collect vast amounts of data on machine performance.

- Predictive Maintenance: AI-powered systems analyze this data to predict potential equipment failures, allowing for proactive maintenance and minimizing downtime.

- Optimized Resource Allocation: Data analysis helps optimize resource allocation, improving efficiency and reducing waste.

- Cost Savings: Predictive maintenance reduces unexpected repairs and replacements, leading to substantial cost savings.

- Improved Production Uptime: By minimizing unexpected downtime, robotic data analysis directly contributes to improved overall production uptime.

This use of AI in manufacturing and data analytics is crucial for Nike's production optimization.

Limitations of Robots in Nike Sneaker Production

While robots excel in repetitive tasks, they have limitations, highlighting the continued importance of human expertise.

The Creativity and Design Process

The creative spark behind innovative Nike sneaker designs remains firmly in the hands of human designers.

- Artistic Vision: Robots lack the artistic vision, intuition, and creativity needed to conceive groundbreaking shoe styles.

- Trendsetting Designs: The ability to anticipate and create trendsetting designs requires human understanding of fashion, culture, and consumer preferences – qualities currently beyond the reach of artificial intelligence.

- Innovation and Experimentation: The process of experimenting with new materials, designs, and technologies requires the human ability to adapt and improvise.

Human ingenuity is irreplaceable in the sneaker design process.

Complex and Customized Production

Many aspects of Nike sneaker production require a level of dexterity and adaptability that robots currently lack.

- Intricate Tasks: Tasks requiring fine motor skills, such as hand-stitching intricate details or working with delicate materials, are best left to skilled human workers.

- Customization Options: Personalization options, such as personalized embroidery or unique material combinations, require human intervention and craftsmanship.

- Flexible Manufacturing: Meeting diverse consumer demands for customized footwear requires the flexibility and adaptability of human workers.

The limitations of robotic automation in meeting diverse consumer demands are evident in the complexities of customisation.

Quality Control and Inspection of Fine Details

While robots ensure consistency, the human eye is still crucial for identifying subtle imperfections.

- Nuanced Judgment: Human inspectors are skilled at identifying minor flaws that might escape robotic detection, ensuring the highest standards of quality.

- Detail-Oriented Quality Control: The ability to assess the overall aesthetic appeal and subtle quality details requires human expertise.

- Maintaining Nike's Quality Standards: Human oversight is crucial in upholding Nike's reputation for premium quality and craftsmanship.

Human inspection maintains the high quality standards expected from Nike products.

Conclusion: The Human-Robot Collaboration in Nike Sneaker Production

The future of Nike sneaker production lies in a balanced approach. Robots enhance efficiency in repetitive tasks such as automated assembly and material handling, improving quality control and reducing costs. However, the human element remains indispensable for creative design, complex customization, and nuanced quality control. The ongoing evolution of human-robot collaboration will shape Nike's production strategy for years to come. Explore the future of Nike sneaker manufacturing and the exciting developments in robotics and Nike's production strategy to understand how this dynamic partnership is shaping the industry.

Featured Posts

-

Trump Administration Targets Harvard With Additional 1 Billion Funding Cut

Apr 22, 2025

Trump Administration Targets Harvard With Additional 1 Billion Funding Cut

Apr 22, 2025 -

Conclave 2024 Assessing Pope Francis Enduring Impact

Apr 22, 2025

Conclave 2024 Assessing Pope Francis Enduring Impact

Apr 22, 2025 -

Are Bmw And Porsche Losing Ground In China A Market Analysis

Apr 22, 2025

Are Bmw And Porsche Losing Ground In China A Market Analysis

Apr 22, 2025 -

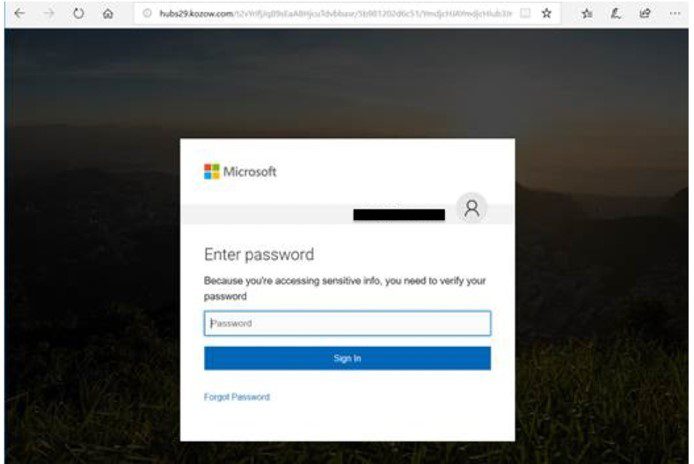

Cybercriminal Makes Millions From Executive Office365 Infiltration

Apr 22, 2025

Cybercriminal Makes Millions From Executive Office365 Infiltration

Apr 22, 2025 -

A Geographic Analysis Of The Countrys Best Business Locations

Apr 22, 2025

A Geographic Analysis Of The Countrys Best Business Locations

Apr 22, 2025