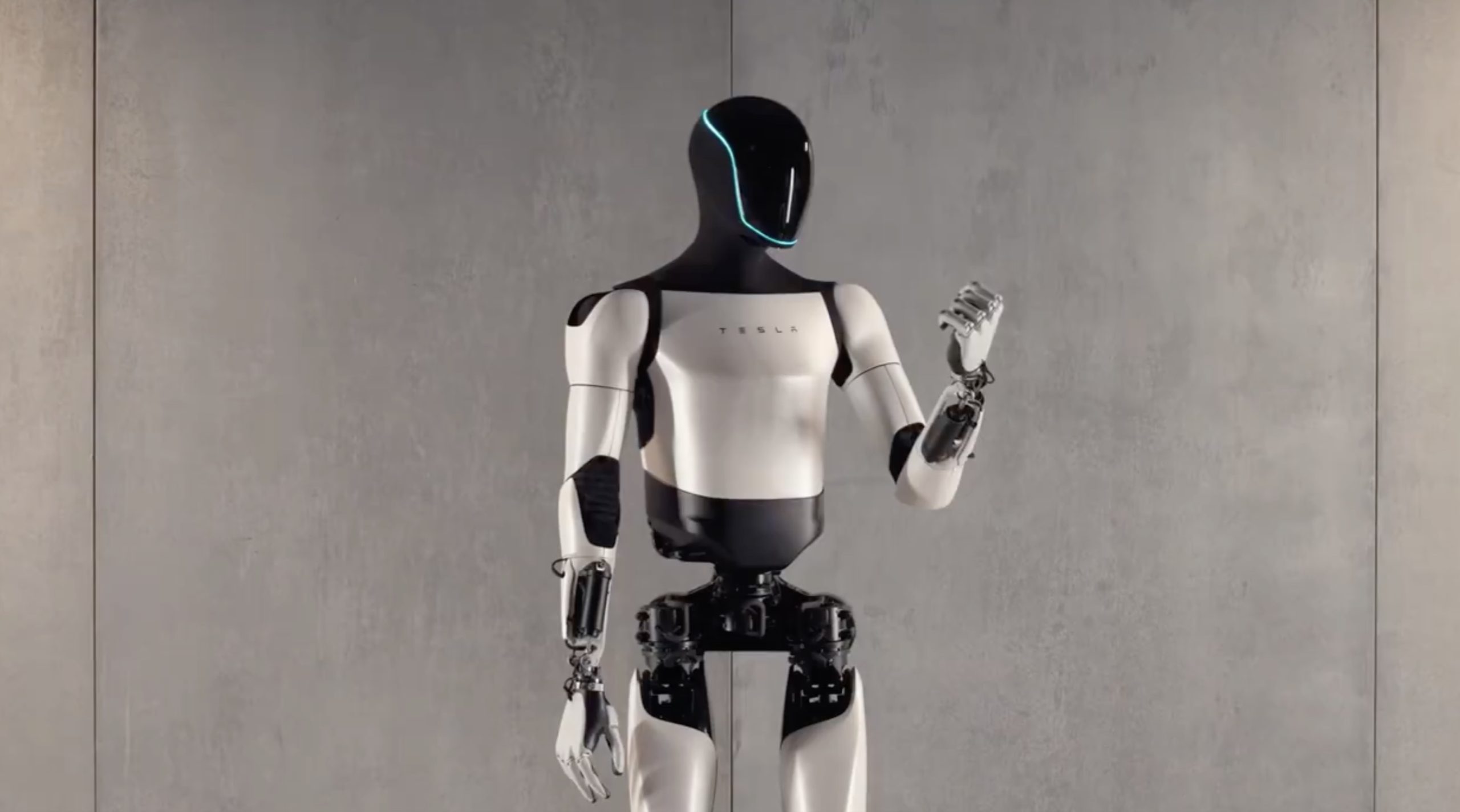

Tesla's Optimus Robot: Navigating The Challenges Of Rare Earth Supply

Table of Contents

The Critical Role of Rare Earths in Robotics

Rare earth elements (REEs) are vital components in numerous parts of the Optimus robot, making them indispensable for its functionality. Their unique magnetic and electrical properties are essential for the robot's precise movements, advanced sensors, and powerful batteries. Without a reliable supply of these minerals, the project faces significant limitations.

- Neodymium magnets in motors: These powerful magnets are crucial for the precise and controlled movements of Optimus's limbs and joints. The strength and efficiency of these motors directly depend on the quality and quantity of neodymium.

- Dysprosium in motors: This REE is essential for preventing overheating in the high-speed motors that power Optimus. Without dysprosium, the motors would be prone to malfunction and failure, severely impacting the robot's performance.

- Other REEs in sensors and control systems: Various other REEs play a critical role in the sophisticated sensors and control systems that enable Optimus's navigation, object recognition, and decision-making capabilities.

- Lithium-ion batteries: While not strictly a rare earth element, lithium is crucial for the robot's power source. The lithium-ion battery supply chain faces similar complexities, including resource scarcity and geopolitical vulnerabilities, impacting Optimus's overall functionality.

Geopolitical Challenges and Supply Chain Vulnerabilities

The global distribution of rare earth minerals is highly concentrated, creating significant geopolitical risks and vulnerabilities in the supply chain. China currently dominates the mining and processing of REEs, a fact that presents considerable challenges for Tesla and other robotics companies.

- Dependence on China: This dependence creates price volatility and potential supply disruptions. Any geopolitical instability or trade disputes involving China can severely impact the availability and cost of REEs, directly affecting Optimus production.

- Trade wars and geopolitical tensions: International relations significantly impact access to REEs. Trade wars, sanctions, and other geopolitical factors can create unpredictable disruptions, hindering the consistent supply needed for mass production.

- Ethical sourcing and environmental concerns: The mining and processing of REEs can have significant environmental and social impacts. Concerns about ethical sourcing and environmentally responsible mining practices are increasingly important for consumers and investors, adding another layer of complexity to the supply chain.

The Impact of Resource Scarcity on Optimus Production and Scalability

Limited access to REEs will directly constrain Optimus's production volume and, consequently, its market penetration. The scarcity of these crucial materials creates several significant obstacles:

- Increased production costs: Fluctuations in REE prices due to supply chain instability lead to unpredictable and potentially prohibitive manufacturing costs.

- Potential delays in market launch: Insufficient REE supply could significantly delay Optimus's market launch and widespread adoption. The inability to meet demand will hinder Tesla's progress.

- Limited scalability: The most significant impact of REE scarcity is the limitation on scalability. Without a reliable and abundant supply, mass production of Optimus remains a distant prospect.

Potential Solutions and Mitigation Strategies

Addressing the rare earth supply chain challenges requires a multifaceted approach involving technological innovation, responsible sourcing, and strategic partnerships. Several strategies can help mitigate these risks:

- Investing in R&D of REE alternatives: Research and development into alternative materials and substitutes for REEs are crucial for reducing dependence on these scarce resources.

- Diversifying REE sources: Reducing reliance on single suppliers by exploring and developing new REE sources globally is vital for creating a more resilient supply chain.

- Developing more efficient recycling processes: Improving recycling technologies to recover and reuse REEs from end-of-life products can significantly reduce the demand for newly mined materials.

- Strengthening international collaborations: Fostering international collaborations and trade agreements to secure stable REE supply chains is essential for long-term sustainability.

- Promoting responsible and sustainable mining practices: Adopting environmentally and socially responsible mining practices is crucial for mitigating the negative impacts associated with REE extraction.

Conclusion

Tesla's Optimus robot represents a significant technological leap, but its success hinges critically on overcoming the challenges posed by the rare earth supply chain. Addressing the geopolitical complexities, resource scarcity, and environmental concerns associated with REE mining is paramount for the future of robotics. By investing in alternative materials, diversifying sourcing, and promoting responsible practices, the industry can pave the way for a sustainable future for humanoid robots. The future of Optimus, and indeed the future of robotics, depends on successfully navigating these rare earth supply challenges. Let's work together to build a more resilient and ethical future for Optimus robots and other advanced technologies.

Featured Posts

-

Tyler Herro Claims Victory In Tight Nba 3 Point Contest Against Buddy Hield

Apr 24, 2025

Tyler Herro Claims Victory In Tight Nba 3 Point Contest Against Buddy Hield

Apr 24, 2025 -

Impact Of Reduced Non Essential Spending On Credit Card Companies

Apr 24, 2025

Impact Of Reduced Non Essential Spending On Credit Card Companies

Apr 24, 2025 -

Trump Affirms Continued Employment Of Federal Reserve Chair Powell

Apr 24, 2025

Trump Affirms Continued Employment Of Federal Reserve Chair Powell

Apr 24, 2025 -

Tzon Travolta Mia Sygklonistiki Mnimi Gia Ton Tzin Xakman

Apr 24, 2025

Tzon Travolta Mia Sygklonistiki Mnimi Gia Ton Tzin Xakman

Apr 24, 2025 -

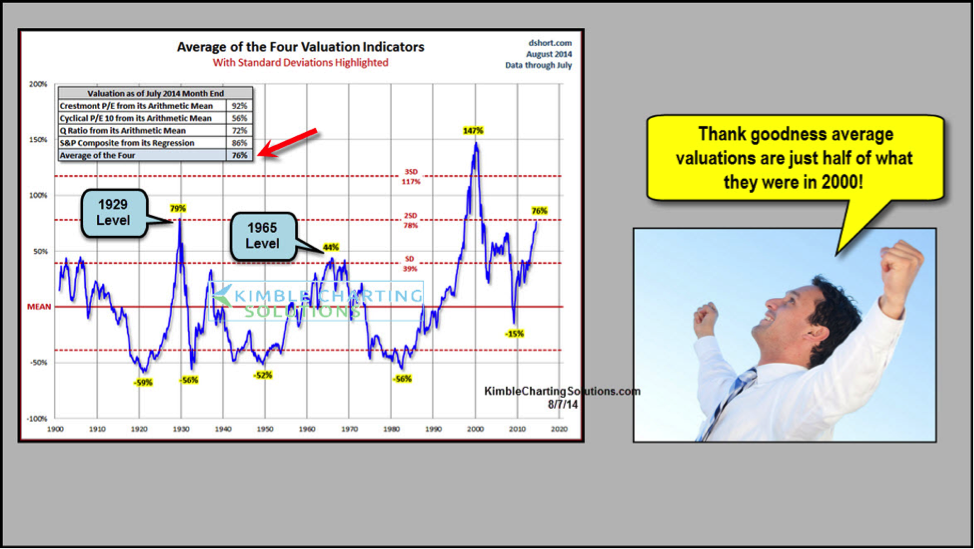

Bof As Take Why Current Stock Market Valuations Shouldnt Worry You

Apr 24, 2025

Bof As Take Why Current Stock Market Valuations Shouldnt Worry You

Apr 24, 2025