Why Nike Shoe Production Remains A Challenge For Robots

Table of Contents

The Dexterity and Precision Hurdle

Shoe assembly is a surprisingly intricate process, demanding a level of dexterity and precision that remains beyond the capabilities of most robots. Human hands possess an unparalleled ability to handle diverse materials and execute complex manipulations with finesse. Current robotic systems, while improving rapidly, still fall short in several key areas:

- Complex stitching patterns and varying material thicknesses: Nike shoes often feature intricate stitching patterns across different material thicknesses (leather, synthetics, mesh), requiring adaptable needle pressure and stitch length control. Robots struggle to adapt seamlessly to these variations.

- Precise placement of components (e.g., laces, insoles): Accurate placement of internal components requires delicate manipulation and force control. Inconsistent placement can lead to discomfort and reduced shoe quality.

- Handling diverse materials (leather, synthetics, fabrics): The range of materials used in Nike shoe manufacturing poses a challenge for robotic grippers. Different materials require different gripping techniques to avoid damage or slippage.

The limitations of current robotic technology stem from the difficulty in replicating the subtle hand-eye coordination and tactile feedback that humans possess. While research into advanced robotic grippers and manipulation techniques using AI-powered vision systems shows promise, widespread implementation remains some time away.

Adaptability and Customization Challenges

Nike’s success is partly due to its diverse range of shoe designs and its increasing focus on customization. This variety presents a significant roadblock for robotic automation. Reprogramming and retooling robots for each new shoe model or customization request is expensive and time-consuming:

- The need for robots to adapt to different shoe models and sizes: Robots currently require significant reprogramming for each new shoe model, making them less efficient than human workers who can adapt more easily.

- The difficulty of integrating customization requests (e.g., personalized embroidery): Adding personalized elements like embroidery or unique color combinations requires flexible robotic systems capable of handling diverse and unpredictable tasks.

- The high cost of reprogramming and retooling robots for each new design: This expense significantly impacts the economic viability of robotic automation for smaller production runs or customized orders.

Current robotic programming lacks the flexibility needed to seamlessly handle the diversity of Nike's product line. Ongoing research into flexible and adaptable robotic systems using machine learning and AI is crucial to overcoming this hurdle.

Economic Viability and Return on Investment

Implementing robotic automation in shoe production is a significant financial undertaking. While automation promises long-term cost savings, the initial investment is substantial:

- The high cost of advanced robotics and related software: The price tag for advanced robotic systems, including programming and integration, is considerable.

- The potential for decreased production speed initially: The learning curve for robots and the need for careful setup can initially slow down production.

- The need for skilled technicians for maintenance and programming: Maintaining and programming advanced robotic systems requires a specialized workforce, adding to the overall cost.

Comparing the cost of robotic automation with the cost of human labor is a complex calculation, requiring careful consideration of factors like labor costs, production volume, and long-term maintenance expenses. The long-term economic viability of robotic automation in Nike's production process remains a critical question.

The Role of Human Expertise and Quality Control

Despite the advancements in robotics, human expertise remains indispensable in Nike shoe production. Certain tasks still require the unique skills and judgment of human workers:

- The importance of human inspection for defects and inconsistencies: Human inspectors can identify subtle defects that automated systems might miss.

- The need for human intervention for complex or unusual situations: Unforeseen problems or highly complex assembly tasks require human problem-solving skills.

- The role of skilled workers in maintaining and troubleshooting robotic systems: Even with advanced robotics, human technicians are vital for maintenance and troubleshooting.

The concept of collaborative robots (cobots), where humans and robots work together, offers a promising path forward. Cobots could handle repetitive tasks, allowing human workers to focus on quality control, intricate craftsmanship, and problem-solving. Upskilling the workforce to work alongside robots will be critical for the success of this approach.

Conclusion: The Future of Robotics in Nike Shoe Production

Automating Nike shoe production faces significant challenges related to robotic dexterity and precision, adaptability to diverse designs and customizations, economic viability, and the irreplaceable role of human expertise in quality control and problem-solving. While full automation remains a distant prospect, advancements in artificial intelligence, collaborative robotics, and specialized robotic systems offer potential solutions. The future of Nike shoe production likely lies in a collaborative approach, where humans and robots work together, leveraging the strengths of each. Continue researching advancements in robotic automation and its impact on the footwear industry, focusing on the ongoing quest for efficient and cost-effective Nike shoe production.

Featured Posts

-

Death Of Pope Francis At 88 A World Mourns

Apr 22, 2025

Death Of Pope Francis At 88 A World Mourns

Apr 22, 2025 -

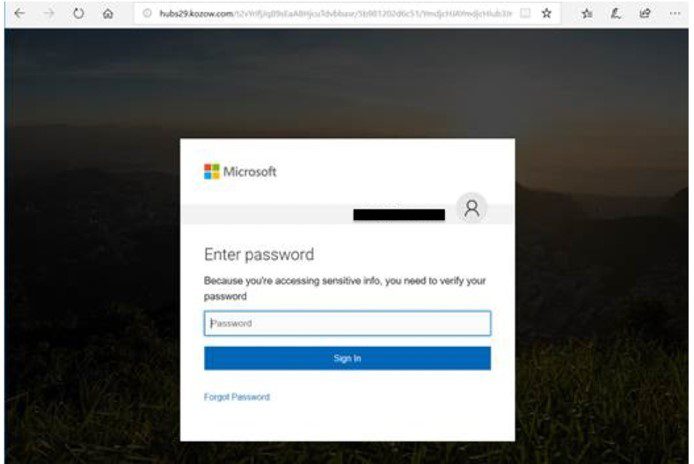

Cybercriminal Makes Millions From Executive Office365 Infiltration

Apr 22, 2025

Cybercriminal Makes Millions From Executive Office365 Infiltration

Apr 22, 2025 -

Cnn Exposes Tik Toks Just Contact Us Tariff Circumvention Strategy

Apr 22, 2025

Cnn Exposes Tik Toks Just Contact Us Tariff Circumvention Strategy

Apr 22, 2025 -

Swedens Tanks Finlands Troops A Look At The Pan Nordic Defense Force

Apr 22, 2025

Swedens Tanks Finlands Troops A Look At The Pan Nordic Defense Force

Apr 22, 2025 -

A Timeline Of Karen Reads Murder Convictions And Appeals

Apr 22, 2025

A Timeline Of Karen Reads Murder Convictions And Appeals

Apr 22, 2025